|

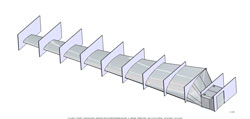

Blade Template Fabrication (1/2):

Templates are defined at specific locations along the blade. Each template defines the airfoil shape and twist.

Blade Drawing

Click image to enlarge |

|

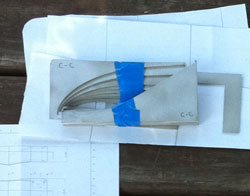

Blade Template Fabrication (2/2):

Templates are water jetted out of 1/16 th Aluminum plate. Each section is marked with a letter corresponding to the station location.

Click image to enlarge |

_THUM.jpg) |

Gluing Wood Planks (1/2):

The drawing to the left defines how to glue wood boards together to form the blank propeller to carve. For this blade I used 3/4" Pine boards. Pine is a soft wood, and easy to carve. I later use a wood hardener to preserve the outside shape and reduce nicking.

Layout Drawing.

Click image to enlarge |

|

Gluing Wood Planks (2/2):

The planks are glued together with Tight bond brand wood glue. It is critical that no air gaps remain, so use as many clamps as possible. I use scrap wood between the clamps and the planks to ensure the clamps don't poke holes in the wood.

Click image to enlarge |

|

Marking The Blade for Carving (1/2):

Mark the planform on the glued-up wood blank. Then cut the planform out using a band saw (this step is completed to the right). Next, mark the stations along the blade span to indicate where the templates will be placed.

Click image to enlarge |

|

Marking The Blade for Carving (2/2):

Mark the leading and trailing edge (leading edge shown to the left).

Click image to enlarge |

|

Carving The Blade (1/5):

Begin removing material, leaving the leading and trailing edge untouched.

Click image to enlarge |

|

Carving The Blade (2/5):

As the blade begins to take shape, the templates are used to check the contour.

Click image to enlarge |

|

Carving The Blade (3/5):

A draw knife is used to hone in the final blade shape.

Click image to enlarge |

|

Carving The Blade (4/5):

Sand the blade.

Click image to enlarge |

|

Carving The Blade (5/5):

Smile for a job well done!

Click image to enlarge |

|

Painting The Blade (1/1):

Add a coat of wood hardener (if you use a soft wood like pine), sand again, then spray paint.

Click image to enlarge |

|

More Blades (1/1):

At this point you can repeat the process two more time and have three blades. Or, in this case, I am going to use the propeller duplicator to duplicate three more blades. Three more blanks are made, awaiting duplication.

Click image to enlarge |

|

Hub (1/1):

The hub is machined from Aluminum. The hub functions by pinning the blades between to plates. Hub drawing (ignore the blade grips, that was from an old design).

Click image to enlarge |

| |

|